Aviation Sector

Technically Advanced

Aviation Sector

Engineered Solutions

AVIATION AND AEROSPACE SPRAY BOOTHS

Throughout Australia companies that work in the aircraft, component and sub-assembly manufacturing industries have relied on TRUFLOW Spray Booths to designed and implement high quality Aviation based spray booths. Working within critical finishing requirements and time frames TRUFLOW’s team is dedicated to providing clients with state of the art combined Heating, Cooling, Spraying and Baking facilities. Each facility is tailor made and it allows for complete environment control and painting conditions to international aviation standards.

Safety & Operator Protection

Aircraft paints are highly toxic, the most critical function of all aviation spray booth systems is to provide an environment that protect the operators against exposure during the painting process. This operator protection is not only the airflow of the booth, it is encompassed into the breathing air apparatus, PPE and the filtration.

Australian Standards Compliance

The Australian Standards for spray booths are regarded as amongst the most stringent in the world; regulated by the 4114:2020 Standards, AS60079 Hazardous Zone Standards as well as Gas and Electrical codes the regulatory requirements of each spray booth must be met and certified in each state. TRUFLOW is licenced and certified to work on Type B Appliances applying both electrical and Gas certifications. Your spray booth will be designed to meet all federal and state guidelines emissions. Filtration systems can be designed by TRUFLOW to handle chromium and cadmium, as well as the mitigation and capture of VOC’s.

Heating and Cooling requirements

Environmental temperature, humidity and cooling controls within an aircraft spray booth is pivotal to effective operation. Modern aircraft paints are best applied in a narrow temperature range to ensure correct atomisation and adequate sub strait temperatures. To help maintain the required temperature and humidity in the paint booth temperature and humidity controls are designed into the supply air handling units.

Stringent Finishing Requirements

Air quality to 10um or 5um on speciality systems provide the cleanest cabin environment. Linear airflow with engineered filtration systems ensure effective finishing in our spray booths for a large range of products. This includes landing gear, business jet aircraft, large aircraft, military ordnance, and helicopters.

Common Applications

- Component Spray Painting

- Landing Gear & Wheel Assembly painting

- Engines / Wings / Cones

- Composite parts

CONTACT US TO SPEAK WITH ONE OF OUR EXPERIENCED ENGINEERS

AIRFLOW TYPES

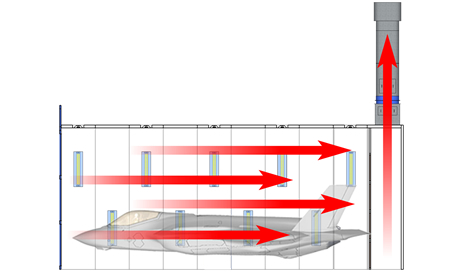

Crossflow

Airflow through front and horizontally across to rear exhaust.

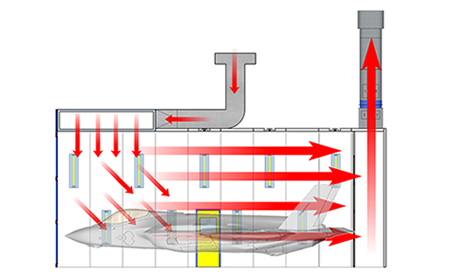

Semi Downdraft

Airflow partially through roof at front and exhaust through rear

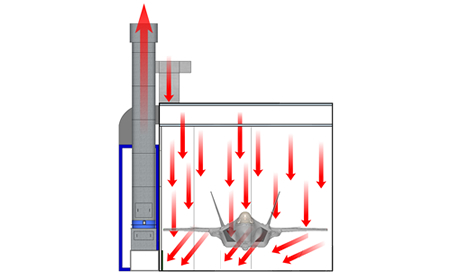

On Floor Side Downdraft

Airflow through full roof area and extraction through either rear, single side or both sides.

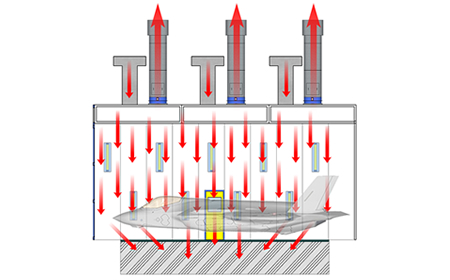

Full Downdraft Pit

Airflow through full roof area and extraction directly under product via concrete pit.

AIR FILTRATION OPTIONS

Paint Stop Filtration

Single stage paint stop filtration utilises dry filter media pads to achieve a capture rate of 99.8% of solid paint particles. This method of filtration is compliant to AS/NZS 4114:2020 Standards and the National Spray Painting Code of practice. Air velocities are designed to capture the atomised paint particulates at the filter point and hold these particulates until changeover is required.

Water Scrubber Filtration

Water filtration scrubbers are also utilised in paint stop filtration in certain spray booth designs. Ideal for higher volume spray painting and also to provide a cleaner environment, the water scrubber system acts as a water trap for both paint and fumes. A water scrubber system can also mitigate VOC’s and is ideal for particularly hazardous aircraft paints that may neutralise in water.

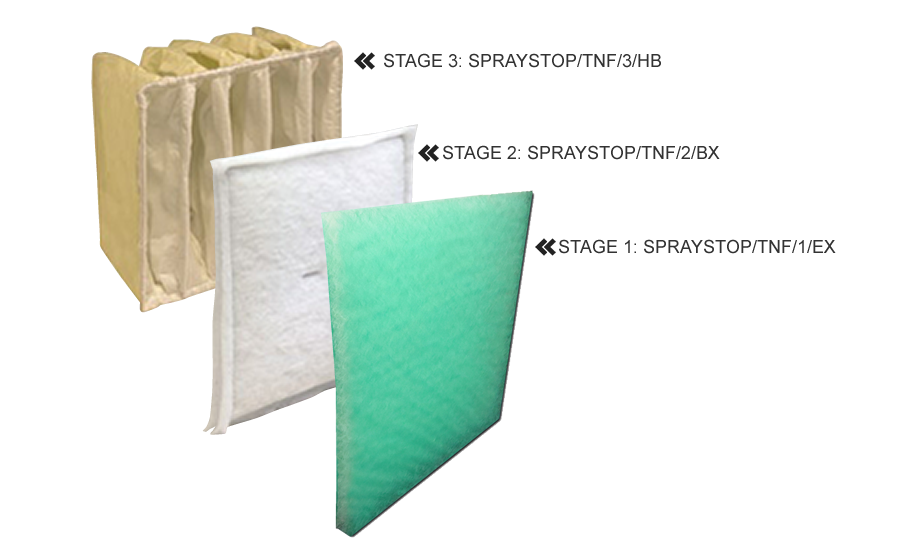

3 – Stage High Efficiency

The aviation industry commonly utilizes chromate based paints including paints that contain chromium in either the primer, base coat or adhesion coats during the painting process. In order to efficiently capture these particles a testing method was developed within the US called the NESHAP 319 standard. This test method ensures that with a specific particulate filter system typically a 1st , 2nd and 3rd stage (Final Filter) ; chromates are captured in the filters prior to the discharge through the spray booth exhaust stack… Read More below

NESHAP 319 AUSTRALIA AVIATION EXAHAUST FILTER

TRUFLOW have developed a high efficiency filter system to remove 95% of particles over 2 micron in size under certain conditions. TRUFLOW has designed and implemented a local Australian made equivalent that can be used within Australia by TRUFLOW’s US client base and defence facilities which have in recent years have been seeking a high efficiency alternative to standard paint stop filtration where in the past traditional filters been unsuccessful in fully capturing chromate based overspray.

The use of a 3-stage filtration system is not mandatory under regulations in Australia however TRUFLOW have researched and developed this product specifically to meet the needs of its client base and in doing so have created a new benchmark in Australian Aviation spraybooths.

This 3 stage Aus-319 filtration system provides 99% removal of most paint spray aerosols. This exceeds the requirements all other spray booth filtration nominated by environmental protection agencies and the code of practice.