Welcome back to Spray Smart, TruFlow’s FAQ series built around the real questions businesses are asking.

Proper airflow is critical for achieving high-quality finishes and keeping your spray booth safe and compliant. That’s why, in this article, we’re answering a common question:

What is good airflow within a spray booth and how much airflow is needed?

In Australia, spray booth operations are governed by stringent guidelines outlined in AS4114:2020 and the Spray Painting Code of Practice. These standards specify minimum airflow requirements to ensure safe and effective operation. However, achieving optimal airflow in a spray booth extends beyond mere compliance. Proper system design is essential to balance the removal of toxic fumes and overspray while maintaining the quality of the painted finish.

This article explores the critical elements of spray booth airflow design and highlights how Truflow’s expertise and products deliver superior performance.

Understanding Airflow Requirements

Effective airflow in a spray booth must strike a delicate balance. The airflow velocity must be sufficient to remove hazardous overspray and fumes from the booth cabin, yet low enough to avoid disrupting the application of finishing materials.

According to Australian standards, the recommended airflow velocities are:

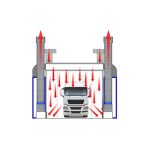

- Horizontal airflow velocity: 0.5 m/s

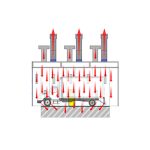

- Downdraft (vertical) airflow velocity: 0.25 m/s

These velocities ensure that the booth environment remains safe for workers while preserving the integrity of the paint application. Achieving these velocities requires careful consideration of the entire airflow system, including filters, ducts, fans, and cabin design.

Key Components of Airflow System Design

1. Filter Design and Performance

Filters play a pivotal role in maintaining consistent airflow across the spray booth’s cross-sectional area. The size, type, and velocity of air through the filters must be precisely engineered to ensure effective removal of overspray and contaminants. Filters must be designed to handle both clean and loaded conditions, as overspray accumulation can significantly impact airflow performance over time.

Proper filter selection and maintenance are critical to sustaining the required airflow velocities and ensuring compliance with safety standards.

2. Ducting and Fan Selection

The ducting system and fans are the backbone of a spray booth’s airflow. Duct velocities must be optimised to minimise turbulence, which can negatively affect the paint finish and increase energy consumption. Fan size and quantity are equally important, as they must provide sufficient airflow volume (measured in litres of air per second) to maintain the target velocities of 0.5 m/s (horizontal) and 0.25 m/s (downdraft).

Fans must also have adequate pressure ratings to overcome resistance from the booth, filters, and ducts, particularly when the system is loaded with overspray after heavy usage.

Additionally, fans should operate quietly, producing noise levels below 85 dBA over an 8-hour period to ensure compliance with workplace safety regulations and minimize worker discomfort during production cycles.

Explore Truflow’s range of spray booth exhaust fans.

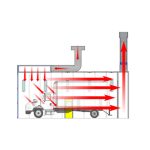

3. System-Wide Considerations

Achieving optimal airflow requires a holistic approach to system design. Key considerations include:

- Cabin size: The dimensions of the spray booth cabin influence airflow distribution and velocity.

- Duct size and configuration: Properly sized ducts reduce resistance and turbulence, improving efficiency.

- Weatherhoods: These protect the system from environmental factors while ensuring consistent airflow.

- Filter surface area: Adequate surface area prevents excessive pressure drops and maintains airflow performance.

By carefully selecting and integrating these components, the system can achieve the desired airflow velocities while minimising running costs and maintaining a high-quality paint finish.

The Truflow Advantage

Truflow’s spray booth systems are engineered to exceed industry standards, offering unmatched performance, efficiency and longevity. Our fans and system designs are specifically tailored to maintain consistent airflow, even under heavy usage conditions. Unlike competing products, Truflow systems are designed to:

- Deliver precise airflow velocities (0.5 m/s horizontal, 0.25 m/s downdraft) for optimal safety and finish quality.

- Minimise turbulence through optimised ducting and fan configurations, reducing energy costs.

- Maintain performance when filters and ducts are loaded with overspray, ensuring long-term reliability.

- Operate quietly, keeping noise levels below 85 dBA to protect worker health and comfort.

Airflow Designs

Truflow’s engineering expertise extends beyond product design. Our team offers comprehensive consulting services, including airflow measurement, system design advice, and rectification of existing spray booths experiencing airflow issues. Whether you’re designing a new spray booth or upgrading an existing one, Truflow provides the knowledge and solutions to ensure your system operates at peak performance.

Conclusion

Effective airflow in a spray booth is critical to achieving compliance with Australian standards, ensuring worker safety, and delivering high-quality paint finishes. By focusing on filter design, ducting, fan selection, and overall system integration, Truflow provides spray booth solutions that outperform competitors in efficiency, reliability, and cost-effectiveness. For expert guidance on optimizing your spray booth’s airflow, contact Truflow today at 1300 266 847 to speak with our team of engineers.